Dressings and Sauces Solutions

ProMach is a dedicated partner for customers in the dressings and sauces industry. From processing raw ingredients to primary packaging for a variety of viscosities, ProMach covers nearly every aspect of the production process. In the dynamic and ever-evolving world of liquid food, ProMach delivers experience streamlined processes, heightened productivity, and product quality to ensure your products and packaging lines are a success.

CUSTOMER HIGHLIGHT

Ken's Foods Continued Growth is Supported by Modern

When Ken's Foods looked to partner with a filling company for their growing business, they turned to Modern. Modern provides Kens Foods with industry-leading cup fillers and they now have 12 Modern filler-packers throughout their four nationwide facilities.

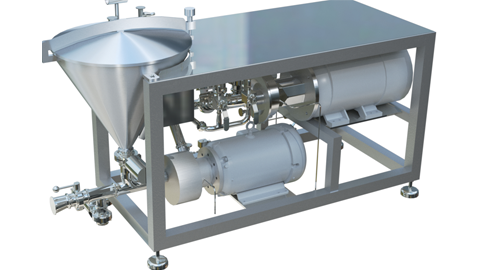

WATCH NOWBlending & Processing

Staco-DSI takes the lead in providing comprehensive support to manufacturers of dressings, condiments, and sauces. Staco-DSI handles every facet of your production process, starting from bulk ingredient receiving and precise recipe-based blending, food safety innovation and improved production rates and positive return on your investment. This ensures your products consistently meet the highest standards, maintaining their quality and flavor with every batch. With an emphasis on the importance of consistency in the dressings and sauces industry, Staco-DSI guarantees that your products will be perfect every time, from conception to completion.

NOTEWORTHY APPLICATIONS

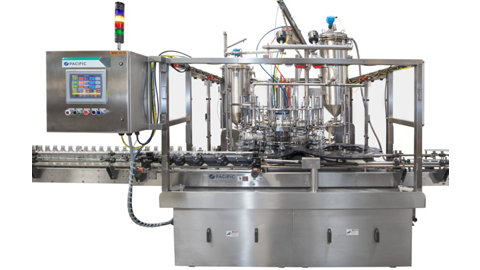

Product Filling

Our lineup of filling product brands, including Modern, Federal, and Pacific, offer comprehensive support to manufacturers of dressings and sauces, covering a wide spectrum of filling needs. From streamlined inline and efficient rotary filling to precise net gravity and volumetric filling solutions, our brands cater to every aspect of your production process.

Modern, Federal, and Pacific provide customers a diverse range of cutting-edge technologies that ensure your products are filled accurately and efficiently, meeting the highest quality standards. Whether your needs involve small-scale batches or large-volume production, ProMach's commitment to excellence ensures that your dressings and sauces are filled with precision and care, every single time.

NOTEWORTHY APPLICATIONS

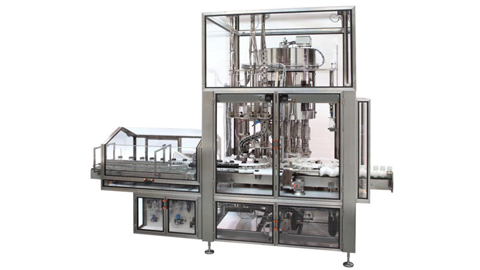

Product Capping

When it comes to securing your products with reliable capping, Zalkin takes the lead as the specialist in high-performance capping and cap handling systems. Zalkin offers a comprehensive range of capping solutions that are not only efficient and durable but also prioritize safety. With a strong commitment to excellence, their solutions cater to a wide array of applications within the dressings and sauces industry. Zalkin's expertise ensures that your products are sealed with precision and reliability, safeguarding the quality and integrity of your products.

NOTEWORTHY APPLICATIONS

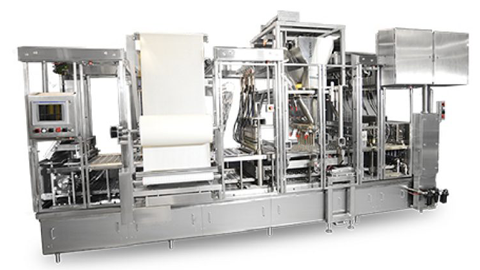

BAGS, STICKPACKS, AND SACHETS

Whether you're bagging dressings and sauces for industrial use or bagging sachets and stickpacks for single-serve, Matrix delivers best in class machinery to fit your production needs. Matrix is the industry expert in vertical form, fill, and seal technology, as well as pre-made pouches, stick packs, and sachets. With a focus on quality, speed, and flexibility, Matrix ensures that your dressings and sauces are packaged with precision.

NOTEWORTHY APPLICATIONS

PRODUCT LABELING

With industry expertise and experience, our product brands are at the forefront of high-speed decorative labeling, tamper evident sleeving, and coding, ensuring that your dressings and sauces are presented with visual appeal. Precision is paramount, and with accurate coding solutions, you can rely on ProMach to maintain the highest standards of information accuracy. Additionally, we offer cutting-edge technology for shrink sleeve application and tamper-evident banding, ensuring product integrity. ProMach's P.E. Labellers, Axon, and ID Technology are here to assist customers in the dressings and sauces industry, ensuring your labeling needs are perfected to the highest degree, enhancing both functionality and visual impact.

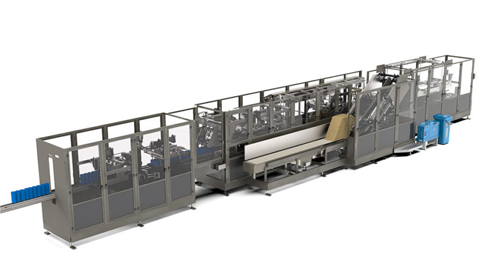

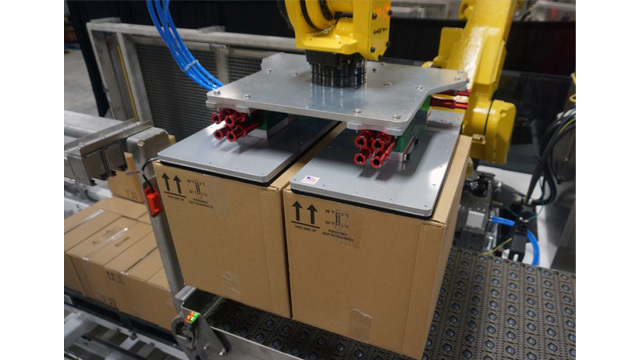

END OF LINE SOLUTIONS

For comprehensive end-of-line solutions, ProMach product brands specialize in a range of critical functions that ensure the seamless and efficient final steps of your production process. From case packing and sealing to seamless secondary conveying, our expertise spans every step of the packaging journey. Further enhancing our offerings, we excel in case palletizing and pallet stretch wrapping, ensuring that your products are secured for transit and storage with the utmost care. ProMach is committed to ensuring your dressings and sauces are prepared for market presentation and distribution with efficiency and precision.

NOTEWORTHY APPLICATIONS

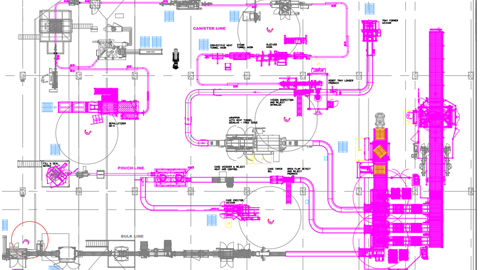

Systems and Integration

Specializing in integrated, OEE availability-optimized turnkey packaging lines, Zarpac offers unmatched expertise in packaging line engineering services. Our capabilities extend to encompass custom packaging equipment design and build, ensuring that your production line is tailored to your specific requirements. With Zarpac as a partner, you'll benefit from experience and innovation, guaranteeing that your dressings and sauces journey through a smoothly integrated production line, setting new standards in efficiency, quality, and productivity.